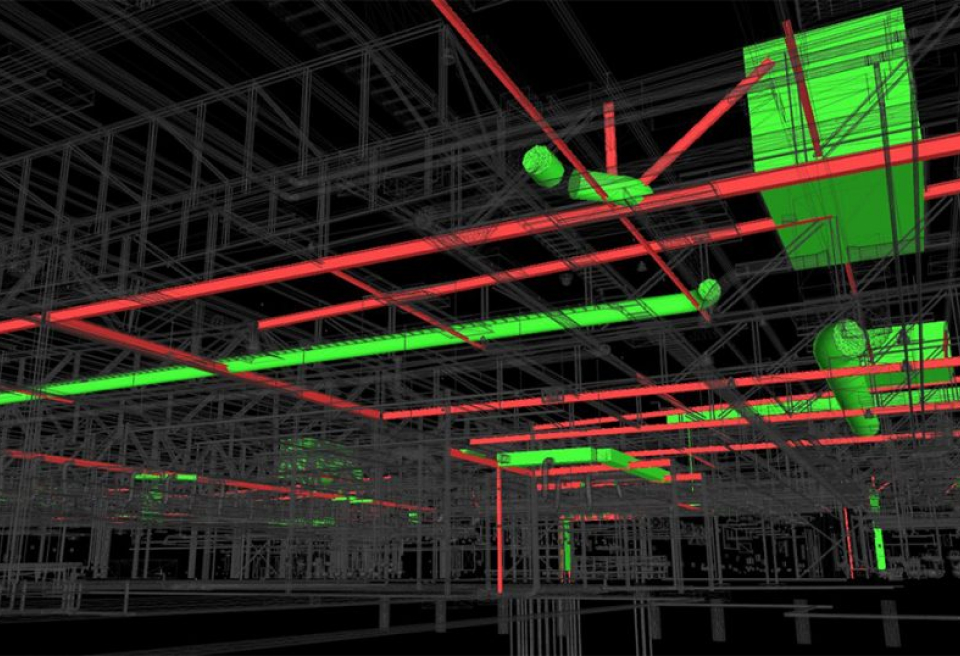

Clash Avoidance, Management and Coordination

In the HVAC/MEP (Heating, Ventilation, and Air Conditioning/Mechanical, Electrical, and Plumbing) business, the service of “Clash Avoidance, Management, and Coordination” is a critical aspect of the design and construction process. It focuses on identifying and resolving clashes or conflicts between various building systems to ensure efficient installation, operation, and maintenance.

Clash Avoidance

During the design phase, clash avoidance involves carefully examining and analyzing the architectural, structural, and MEP plans to identify potential clashes between different building systems. These clashes could include conflicts between ductwork, piping, electrical conduits, equipment locations, or spatial constraints. By identifying these clashes early on, it becomes possible to modify the design or adjust system layouts to minimize conflicts.

Clash Management

Clash management involves coordinating with different trades and disciplines to address clashes that have been identified. It may require collaboration between HVAC engineers, electrical engineers, plumbing designers, structural engineers, and other relevant stakeholders. The aim is to develop solutions that resolve the identified clashes while considering factors such as system performance, code compliance, energy efficiency, and maintainability.

Clash Coordination

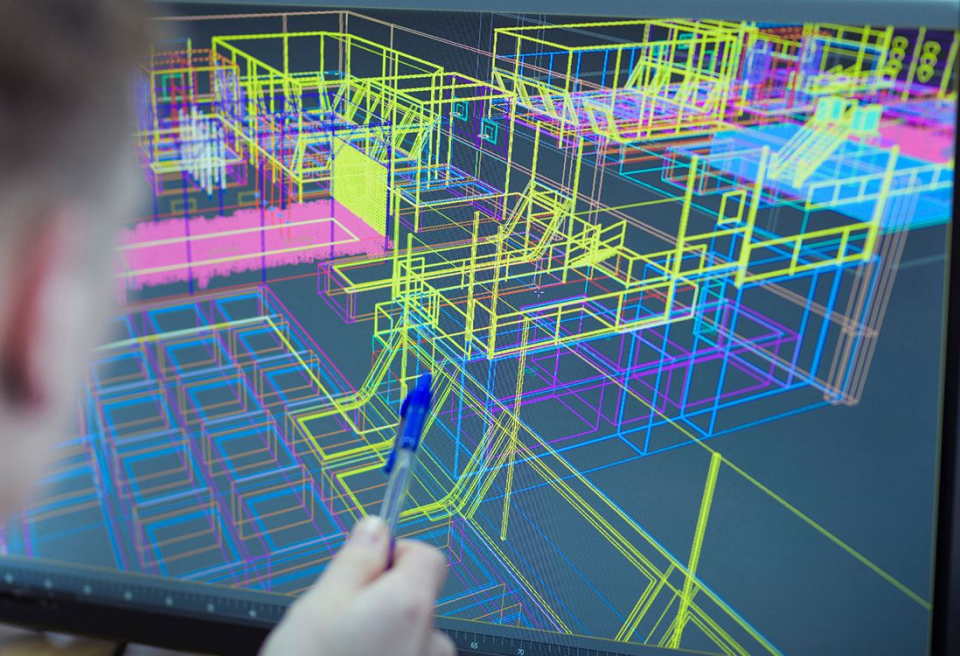

Clash coordination involves effectively communicating and coordinating the resolution of clashes among the project team. This includes regular meetings, discussions, and the use of Building Information Modeling (BIM) software or other computer-aided design (CAD) tools. Clash coordination ensures that all parties involved are aware of the clashes, understand the proposed solutions, and work together to implement them.

Summary

By providing clash avoidance, management, and coordination services, HVAC/MEP professionals help prevent costly and time-consuming conflicts during the construction process. This service ensures that the different building systems can be installed and integrated seamlessly, optimizing system performance and minimizing the risk of rework or delays.

DCMvn CO LTD are able to use Client 2D information and formulate a 3D Model with associated data, enhancing the potential of the project in terms of efficiencies & design validation.